PAMHS provides specialist on-site servicing and installation of rotary and diverter valves for industrial powder handling systems. We help minimise downtime, improve performance and keep your equipment running reliably.

Servicing

Our servicing options cover everything from one-off equipment condition assessments to fully managed annual service agreements. Our multi-skilled engineering team works across a wide range of powder handling equipment, providing a complete support solution for your plant.

We tailor each service to your needs, whether it’s a visual inspection or a more comprehensive maintenance programme. Our focus is to improve system reliability, increase efficiency and extend the life of your equipment through proactive optimisation.

After every service, we supply a detailed report outlining the condition of each item of equipment along with recommended corrective actions. Regular maintenance is essential for keeping systems operating reliably, and we work closely with your in-house maintenance teams to define routine checks that should be carried out between service visits.

Installation

PAMHS provides professional installation and commissioning of rotary valves, diverter valves and associated powder handling equipment. Our engineers ensure correct alignment, sealing and integration into your existing process, ensuring safe and reliable operation from day one.

Contact us to discuss your installation requirements and how we can support your project.

Refurbishments

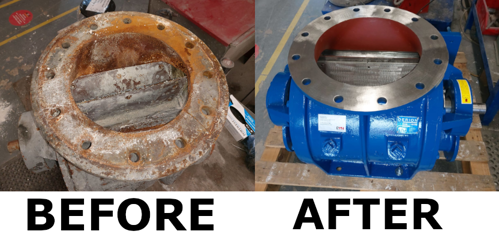

PAMHS specialises in rotary valve refurbishment, rotary valve repair and diverter valve repair for industrial powder and bulk material handling systems. Our engineers can carry out on-site servicing where removal is difficult, although full workshop refurbishment provides the highest level of restoration and reliability. To reduce downtime, we also offer service exchange rotary valves.

As the exclusive Approved Accredited Service Partner for DMN Westinghouse in the UK and Ireland, PAMHS is certified to refurbish DMN rotary valves to factory standards, including ATEX and APS compliant models. Our team is trained directly by DMN Westinghouse and has extensive experience repairing rotary and diverter valves from Rotovalve, Bühler, Reimelt, Zeppelin, Rotolok, Wamgroup, Gericke, Nordfab and other major manufacturers.

Every refurbishment includes complete assessment, reporting and a clear quotation before any work begins. We restore valves to original performance, improving reliability, airflow accuracy, hygiene and system efficiency while offering a cost-effective alternative to replacement.

If a rotary valve or diverter valve is beyond economical repair, PAMHS can provide replacement recommendations and support full installation and commissioning through our technical service team. Our goal is to maximise equipment lifespan, reduce unplanned downtime and keep your powder handling systems running at optimal performance.